MPTI has the knowledge and technology to meet our customers IMD/FIM injection molded component needs efficiently and on-time with a cost savings.

Video: © KURZ 2019

MPTI is vertically integrated supplier of IMD/FIM decorated parts with all processes in-house.

Our clean, organized manufacturing area utilizes industry leading In-line thermoforming equipment, state of the art injection molding machines and custom-built trim presses for the Insert mold decorating process

The MPTI engineering team is capable of leading or assisting customers with R&D projects analyzing new materials, processes or technologies. Start to finish, we collaborate with customers to design and engineer parts that meet world standards for production accuracy, fit and finish.

- In-house design and tooling

- CAD/CAM systems for ultra-precise part design and tooling

- CNC mills create complex, highly-detailed shapes

- Multi-cavity molds deliver dimensional repeatability

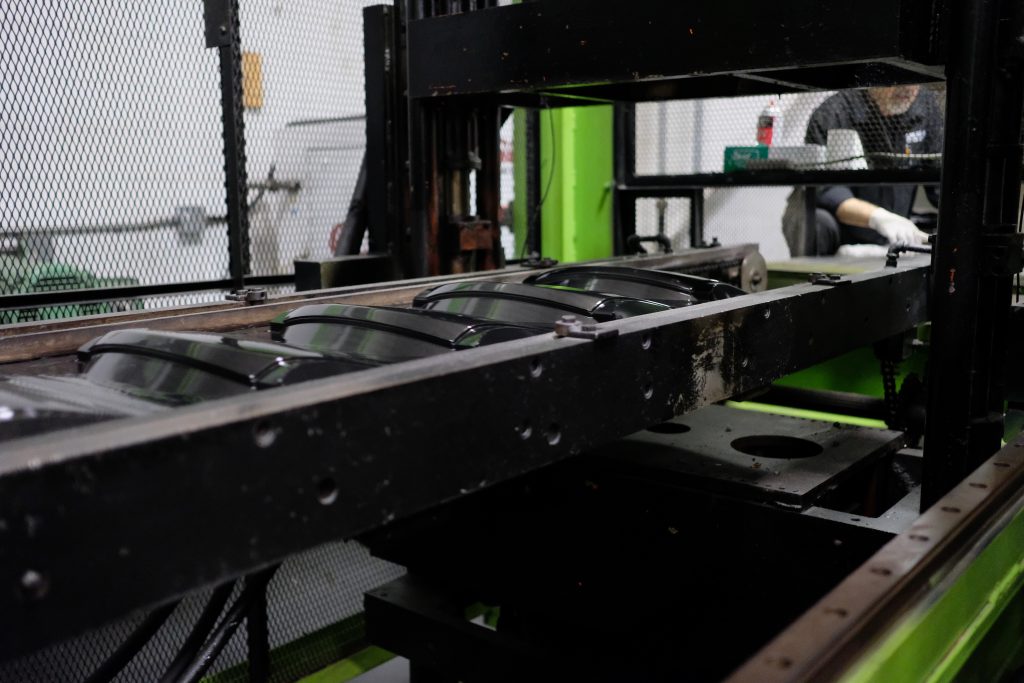

In-line Thermoforming

Our in-Mold appliqué products are produced through a multi-step process that uses a printed film—typically an ABS, Polycarbonate, or TPO. We use high-speed, in-line presses with pressure assist. We maintain precise temperature control both in our materials and tooling. All these components lead to a controlled process that is highly repeatable enabling us to meet the most demanding quality requirements.

- ABS, polycarbonate, TPO and other polymers

- Precise temperature control on materials and tooling

- Highest quality thermoformed parts with consistent, repeatable metrics

Trimming

We can accurately reproduce the most intricate designs—including reverse angles and wrapped parting lines. Our expert Trim Technicians are trained and thorough. We consistently meet the demanding tolerances established by our quality engineers and our customers. Every part is inspected and handled with care to meet functional and visual requirements.

- Highest precision for fit and function, even for reverse angles and wrapped parting lines

- Production personnel highly trained with years on Applique experience

- Careful inspection and handling assure 100% defect free parts

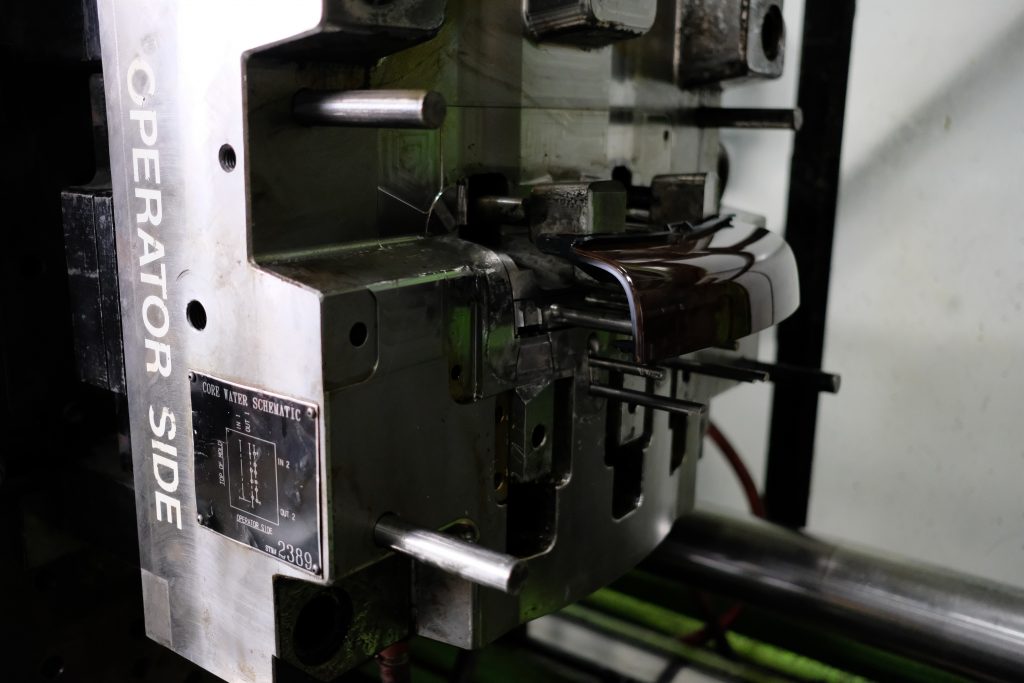

Film Insert Molding (FIM/IMD)

MPTI provides high-quality decorative finishes in injected parts, with great resistance to both wear and tear. In-Mold Decoration (IMD), also known as Film Insert Molding (FIM), is a versatile, cost-effective method for producing and decorating durable three-dimensional plastic parts.

Our team at MPTI has years of experience in the manufacture of decorative injected parts using machines ranging from 100 to 2500 ton.

- Extensive experience with model refresh and differentiation

- Flexible collaboration with OEMs and Tier 1 & Tier 2 designers

- Expertise in functional, value-added processes (assembly, pad printing, etc.)