MPTI thermoforming/vacuum forming service offers our customers a cost-effective solution from prototype fabrication to full production runs.

Whatever your needs may be, MPTI can put our engineering, design & manufacturing expertise to work to create the right product for you.

Heavy Gauge Thermoforming

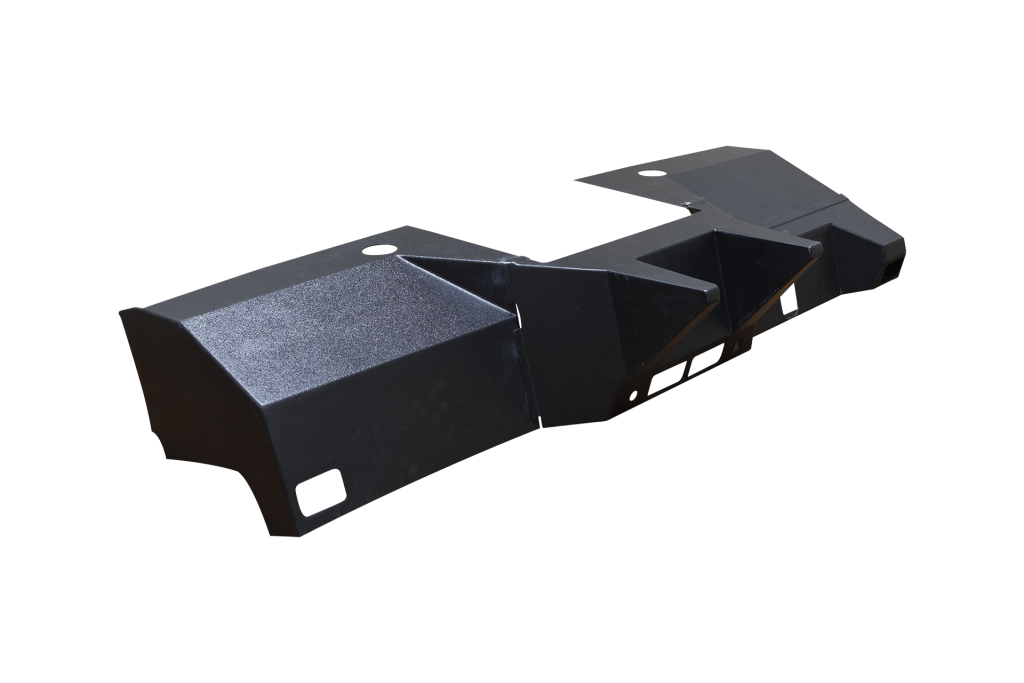

MPTI has multiple process capabilities to improve your brands and the quality of your products. Our engineering and manufacturing group provides vacuum formed, pressure formed, and lightweight reinforced products and assemblies, using a variety of different materials and components.

The process of transforming a flat sheet of plastic into a three-dimensional functional form is called heavy gauge thermoforming (or heavy gauge plastic thermoforming). The plastic sheets are first heated; then, using either a vacuum press or pressure, they are formed into a mold so that they take the shape desired by the customer.

Heavy gauge thermoforming is excellent for large parts and permanent structural components, especially those that must withstand high levels of stress. The parts can be used either indoors or out, depending on customer specifications. Heavy gauge thermoforming can also be used when it is necessary to create multiple parts and not cost-effective to use injection molding.

Because this type of custom thermoforming is so flexible, it is suitable for a wide variety of applications. Heavy gauge plastic thermoforming can be used to create everything from totes and bins to pallets, truck components, fitness equipment, agricultural components, guards and bezels, housings, and more.

At MPTI, we have a wide range of custom thermoforming capabilities to serve you. Learn more about what we can do for you today.

Thin Gauge Thermoforming

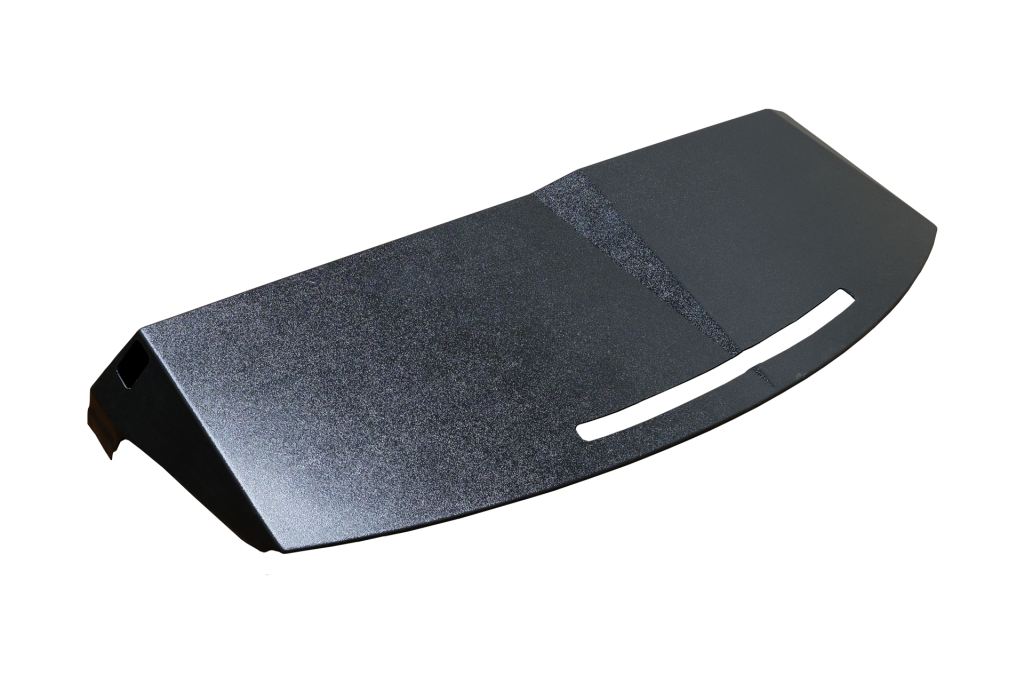

Thin Gauge thermoforming is a process that converts a flat sheet of plastic into a functional form usually used in packaging. Materials typically run between .010″ to .060″ thick. The most common uses are for food, dunnage, and retail packaging.

MPTI has built thin gauge thermo forming expertise throughout the years and understands how to successfully deliver thermoformed products on-time, high quality, zero defect and on budget.

We specialize in medium volume, complex shaped containers, trays and dunnage. Our top-notch tooling is highly competitive and provides rapid-turnaround which ensures that your product gets to market faster.

Quality thin gauge thermoformed products begin with quality tooling. At MPTI we make our production tools from machined aluminum and add temperature controlling to ensure an accurate replication of the mold surface and part to part consistency.

The most commonly used materials include ABS, HIPS, PETG, PVC and PC. However, several other specialty materials are available and can be provided based on your needs.

Our team of qualified designers can help you create anything from complex material handling trays that protect sensitive components, a retail package that adds pizazz and security to your product, or even a simple drip tray to protect your equipment from caustic fluid damage.

Our Custom Thermoforming Capabilities Include:

- Heavy Gage, Thick Sheet Vacuum Forming (0.06” to 0.375”) of HDPE, LDPE, LWRT, ABS, PC etc.

- Thin Gage, Inline Vacuum Forming (0.10” to 0.06”) of ABS, HIPS, PETG, PVC, PC etc.

- Single sheet thermoforming

- Heavy gauge thermoforming

- Thin Sheet Thermoforming (Continuous or Sheet fed)

- CNC trimming

- Steel Rule Trimming

- Match Metal trimming

Additional services available:

- Major & minor value-added assembly

- Secondary assembly, bonding, inserting

- CNC Robotic trimming for product assembly and fixturing

MPTI can help you with heavy and thin gauge plastic thermoforming, custom thermoforming, and more. Contact us today to learn more about our thermoforming services!